Message from the Director in Charge of the Environment

As a specialized seat manufacturer whose mainstay product is automotive seats, TACHI-S works across the globe to

provide safe, comfortable mobility spaces. As such, we are highly conscious of the growing expectations and

demands on the automotive industry around the globe to be considerate of the environment.In particular, reducing

greenhouse gas emissions by reducing the fuel consumption of automobiles by reducing the weight of products and

reducing the energy use of the manufacturing process of products, and contributing to a recycling-oriented society

by saving resources and a low-carbon society by saving energy. We believe that this is not only an important area

of contribution that we can work on to solve global environmental problems, but also a strategic theme that is

directly linked to improving the competitiveness of our products in response to customer requests.

For the realization of a sustainable mobility society, TACHI-S, together with its stakeholders, will strive to

continuously reduce the environmental impact of its products and business activities. The entire TACHI-S Group

will promote environmental conservation activities to ensure a global environment where future generations can

live happily.

Yoshiaki Kubo,

Director and Executive Managing Officer

in Charge of the Environment

Environmental Policy

In the belief of the importance of passing on our precious global environment to future generations and of promoting

Group-wide activities for environmental conservation to realize a society in which people and nature can coexist,

TACHI-S established its Environmental Policy in 2000. This policy clearly states the key areas of TACHI-S’s

environmental activities, including compliance with environmental laws and regulations, the reduction of greenhouse

gas emissions, and the development of environmentally-friendly products.

1. Basic Philosophy

A company that is kind to people and nature

Setting “kindness,” or consideration of people, society, and nature, as the foundation of its

manufacturing,

TACHI-S will raise all employees’ correct awareness of the environment and commit proactively to the

protection of

the global environment, to contribute to the realization of a rich society in which people and nature can co-exist.

2. Environmental Policy

In all business activities related to development, design engineering, purchasing, and production of automotive

seats and related components, TACHI-S will promote periodic reviews of its activities to achieve the environmental

goals and targets and environmental management system established by the Company, and reduce our environmental

impact.

- (1)We will comply with environment-related laws and regulations, ordinances,

agreements, and industry standards and regulations in Japan and overseas to prevent environmental pollution.

- (2)We will promote the reduction of greenhouse gas emissions by improving efficiency

through the continuous improvement of business operations.

- (3)We will strive to develop environmentally friendly products and methods and

reduce our use of hazardous chemicals by transitioning to alternative substances.

- (4)We will promote the conservation of resources and energy, strive for a proactive

co-existence with local communities, and aim toward full employee participation in environmental protection

activities by raising the environmental awareness of each employee.

Yoshiaki Kubo, Chairman of the Company-wide Environment Committee

june 6, 2023

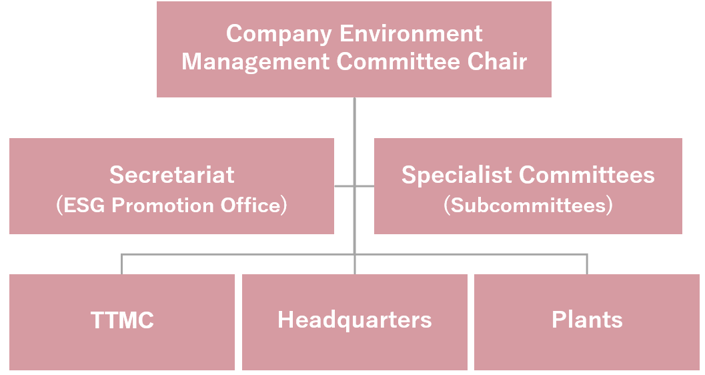

Environmental Management Structure

System for Promotion of Environmental Conservation Activities

To promote company-wide environmental conservation activities, TACHI-S established the Company Environment Management

Committee (Secretariat: ESG Promotion Office), with the Executive Managing Officer serving as chair, the

individual Division Managers as deputy chairs, and representatives of the individual locations as members. This

committee, which meets quarterly, manages environmental protection activities at Headquarters and individual

plants.

Three specialist subcommittees also engage in activities on different topics.

Environmental Management System

TACHI-S introduced the ISO 14001 environmental management system in 2001 to continuously improve its environmental

conservation activities. Currently, locations, including headquarters, have obtained external certification.

Affiliated companies have acquired ISO 14001 external certification for environmental management systems at their main

bases in Japan, North America, China, and Thailand.

| TACHI-S |

- Head Office Technical Monozukuri Center

- Aichi Plant

- Musashi Plant

- Tochigi Plant

- Suzuka Plant

- Advanced Technology Center

|

Affiliated companies

*consolidated subsidiaries

As of Octoder 2025 |

- TF-METAL U.S.A., LLC

- TACHI-S H&P Co., Ltd.

- Nui Tec Corporation

- SETEX Automotive Mexico, S.A. de C.V.

- Wuhan Dongfeng TACHI-S Yanfeng Automotive Seating Co., Ltd.

- Hunan TACHI-S Automotive Seating Co., Ltd.

- Lear Dongshi TACHI-S Automotive Seating (Wuhan) Co., Ltd.

- TACHI-S Automotive Seating (Thailand) Co., Ltd.

|

Environmental Education

Scene from environmental education program for new employees

Guided by the Environmental Policy, TACHI-S has committed to promoting effective environmental conservation activities. To support this, we have established clear procedures for training employees involved in these efforts and carry out educational programs in a planned and systematic manner. We also provide introductory training for new employees to help them gain a solid understanding of the basics of environmental conservation.

Environmental Risk Management

Emergency response drill for a chemical leak at the Technical Monozukuri Center

Envisaging the environmental impacts of an emergency at one of its locations, TACHI-S has established procedures

for the prevention and mitigation of such impacts and conducts maintenance and management accordingly. Further,

envisaging an emergency situation caused by an actual accident, we also conduct emergency response drills

systematically.

Environmental Audit

For ISO14001, TACHI-S undergoes systematic internal audits and certification assessments by external specialized

institutions, to ensure that its environmental management system is being properly maintained and implemented. We also

conduct systematic training of internal auditors.

Status of implementation of environmental audits

Environmental Issues and Targets

Relationship between TACHI-S’s Business Activities and Environmental Impact

In the manufacture of automotive seats, TACHI-S uses metals for the base of the seat frame and non-metallic materials such as urethane, fabrics, leathers, and plastics.

We also use electricity and other energy in our manufacturing processes. To minimize greenhouse gas emissions from our production activities, we strive to reduce emissions, with a particular focus on processes with high energy consumption such as frame welding. Regarding the use of water resources, the cooling water for welding equipment is used in a recirculating system. In other seat manufacturing processes, water usage is limited.

Material Environmental Issues

Identification of Material Environmental Issues

We consider “response to climate change issues,” “chemical management,” and

“sustainable use of resources” to be

material management issues that are closely related to our business activities and engage in initiatives to solve

these issues.

Material environmental issues

- Response to climate change issues (reduction of greenhouse gas emissions, adaptation to climate change)

- Chemical management (reduction of hazardous chemicals, prevention of environmental pollution)

- Sustainable use of resources (improvement of resource utilization efficiency, reduction of waste materials)

Environmental Risks and Opportunities

We recognize the following risks and opportunities of our business activities caused by material environmental

issues.

We believe that reducing these risks and responding appropriately to business opportunities will help to solve

environmental issues and enhance our corporate value.

TACHI-S’s environmental risks and opportunities

Environmental Targets and Achievements

The initiatives, goals, and achievements of environmental conservation activities for the FY2024 were as follows.

- To reduce greenhouse gas emissions, we worked on energy-saving activities by improving daily work and CO₂ emission reduction by solar power generation. Interms of facilities,we have systematically switched to LED lighting and energy-saving air-conditioning equipment throughout the company, and reduced power waste through facilities that visualize power.

- To reduce harmful chemical substances, we are focusing on reducing defective products in the integral foaming process (the process of foaming urethane to form headrests, etc.).

- Regarding final disposal waste (landfill waste), we set a target of zero and have been thoroughly promoting waste separation to achieve this goal.

Annual environmental targets and results (TACHI-S business locations in Japan)

* In calculating the basic unit, the CO2 conversion coefficient is fixed

so that

voluntary improvement can be evaluated.

* Non-recyclable waste is treated by thermal recycling, the result of which is the

achievement of zero final disposal waste, which equals zero emissions.

Climate Change Issues

Basic Concept and Approach

Global warming and the accompanying climate change are causing melting glaciers and rising sea levels, floods and

droughts, as well as impacts on human lifestyles and natural ecosystems, including land and marine ecosystems, food

production, and health. Amid calls for the reduction of greenhouse gases to prevent climate change, TACHI-S is working

to reduce CO2 emissions from driving (Scope 3) with the lightweighting of its seats and the reduction of

CO2 emissions

from its manufacturing processes (Scope 1 & 2).

Basic Policy on Climate Change Response

As its contribution to the various governments’ carbon neutrality goals, “Carbon Neutral in 2050*,”

TACHI-S has set a

new target for CO2 emissions reductions of 46% (domestic) compared to FY2013 in 2030 and 43% (overseas)

compared to

FY2019 in FY2030. In our plants and offices, we will engage in the reduction of CO2 emissions by cutting

down on

energy consumption through the promotion of energy conservation and shift to low-carbon energy, including the

introduction of renewable energies. We will also adopt and develop carbon-free raw materials to reduce CO2

emissions

across the lifecycle of our products and strive to reduce CO2 emissions throughout the entire supply chain.

* Production volume intensity target for Scope 1 & 2 in Japan

- We will engage in the reduction of CO2 emissions through energy conservation at our business locations,

day-to-day

improvements in production processes, and the transition to power-saving production equipment.

- We will engage in the reduction of CO2 emissions through changes in product specifications and

manufacturing

processes.

- We will promote the introduction of renewable energies.

- We will strive to reduce CO2 emissions throughout the entire supply chain.

- We will disclose information appropriately to Stakeholders.

Efforts to Prevent Climate Change

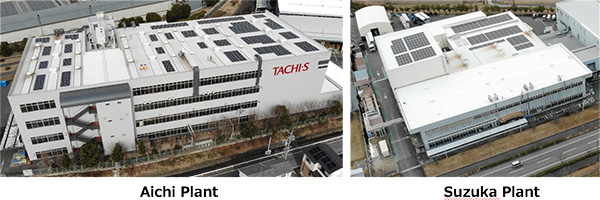

Tachi-s has set company-wide CO₂ emissions reduction targets and are continuously promoting efforts to reduce emissions. In addition to reduction activities through daily improvement activities, we are working to reduce CO₂ emissions per unit of production and total emissions by switching to LED lighting, introducing energy-saving air conditioning equipment, and introducing electric and hydrogen vehicles to company vehicles. In addition, we have introduced solar power generation equipment, with Aichi Plant and Suzuka Plant starting to generate electricity in fiscal 2022 and Musashi Plant (machine building) starting in fiscal 2023, and Musashi Plant (second plant) also starting to generate electricity in fiscal 2024.

Trends in total energy consumption

TACHI-S and consolidated group companies

Consolidated (including TACHI-S)

※1 Fuel:Uses coefficients based on "Greenhouse Gas Emissions Accounting, Reporting and Disclosure System (Japan)"

※2 Electricity:Uses 3.6 GJ/1000kWh

Trends in total greenhouse gas emissions and greenhouse gas emission intensity

(TACHI-S business locations in Japan)

Trends in greenhouse gas emissions (By scope)

※ Total emissions are calculated based on market criteria.

Greenhouse gas total emissions of Affiliated companies(Scope1 and 2)

Japan region *Except TACHI-S

North America region

Latin America regions

China region

Asia region

Efforts to Adapt to Climate Change

With the aim of adapting to climate change, as a measure to prepare for responses to natural disasters, which are

increasing in line with climate change, pocket disaster-prevention manuals have been distributed to employees. We are

also pursuing initiatives to minimize risks in the event of a disaster. They include basic actions to be taken in the

event of natural disasters, the establishment of a disaster readiness response headquarters, and a safety confirmation

system.

Efforts to Achieve a Circular Resources Economy

Basic Concept and Approach

Demand for natural resources such as fossil fuels and rare earths is expected to continue growing with future global

population increases and economic development. As a country that relies heavily on imports for its resources, for

Japan to continue to develop sustainably, it will need to create a circular economy for resources by further reducing

their consumption and improving the efficiency of their use.

TACHI-S develops and manufactures automotive seats and other products, procuring and utilizing raw materials such as steel, resin parts, fabric (cloth), leather, urethane, and rubber, as well as packaging materials, electricity, fuel, water, and other resources and energy.

We aim to contribute to the realization of a resource-circulating society by reducing material usage, promoting the use of recycled materials, and utilizing renewable energy.

Basic Policy on Conservation of Resources

With the aim of creating a circular economy that balances the environment and economy for the sake of sustainable

development, TACHI-S will work to use limited resources efficiently in the individual stages of development,

production, and disposal.

- We will work to reduce the size and weight of parts.

- We will strive to reduce waste by increasing yield and reducing defects in the manufacturing process.

- We will promote the use of renewable energies and recyclable resources.

- We will disclose information appropriately to Stakeholders.

Initiatives for the Conservation of Resources

TACHI-S undertakes initiatives for the conservation of resources in the development and production stages.

Specifically, development-stage initiatives include the lightweighting of seats(Weight reduction through material reduction, etc.), cutting down on the number of component parts, and efforts to improve yield (minimizing offcuts when

cutting fabrics and leather).

In the production stage, we strive to reduce defects (reduction of defects in the integrated foaming process), and to

cut down on packaging materials (switch from one-way cardboard containers to re-usable plastic containers).

Trends in total waste volumes(TACHI-S business locations in Japan)

※Excluding valuable materials

※Hazardous waste(e.g., fluorescent lamps, dry batteries)

※Hazardous waste(e.g., fluorescent lamps, dry batteries)

Trends in the total emissions of valuable materials(TACHI-S business locations in Japan)

Paperless activities and achievements(TACHI-S business locations in Japan)

We have been working on paperless activities since fiscal 2019. We are working to reduce the number of printed pages by promoting electronic document management in accordance with regulations, electronic expense settlement and invoices, and electronic distribution of documents. We continue to utilize digital technology to improve productivity and establish paperless operations regardless of where we work.

Water Resources Management

Basic Concept and Approach

With climate change due to global warming and the rapid population growth of recent years, the risk of shortages in

water resources is increasing in some regions. To use limited water resources wisely, we strive to reduce water usage

in our production processes, as well as saving water in our facilities in general.

Basic water resources policy

TACHI-S will work to effectively utilize limited water resources with the aim of creating a recycling-oriented

society that balances the environment and the economy for sustainable development.

- We will work on recycling water resources such as recycling cooling water and wastewater in the production

process.

- We will strive to reduce the amount of water used in the facility.

- We will monitor wastewater regularly and conduct appropriate wastewater treatment.

- We will disclose information appropriately to stakeholders.

Initiatives and Achievements in Water Resources Management

As a result of water saving efforts in our facilities, we achieved a 6.8% reduction year-on-year in water resource

input to 24,890 m3.The volume of wastewater output was the same as water resources input.

Trends in water resources input (TACHI-S business locations in Japan)

Chemical Management and Pollution Prevention

Basic Concept and Approach

Chemical substances discharged into the environment are potential causes of air pollution and water pollution. If

they accumulate in the soil over long periods of time, they may also adversely affect ecosystems and human health.

TACHI-S uses chemicals in the integrated foaming process and other processes. We promote initiatives for the proper

management of chemicals and the reduction of hazardous chemicals.

Basic Chemical Management Policy

Throughout the product lifecycle of development, production, purchasing, distribution, use, and disposal, TACHI-S

will properly manage and reduce the use of chemicals that are regulated under laws and regulations, ordinances,

agreements, and industry standards that apply in countries and regions where it conducts its business, for the

safety and peace of mind of customers, suppliers, and employees.

- In product development, we will identify the chemicals and their quantities in use, manage them properly, and

develop technologies for their reduction.

- We will identify the quantities of chemicals used in product manufacturing processes, manage them properly, and

reduce their use.

- We will identify the impact of chemicals in the sales and distribution processes and manage them properly.

- We will educate employees about the risks involved in the handling of chemicals and strive to make them aware of

the need for chemical management.

- We will disclose information appropriately to Stakeholders.

Initiatives and Achievements in Chemical Management

We strive to properly manage the chemicals contained in our products and those used in our production processes. We are working to reduce the use of hazardous chemicals and switch to substances that have a lower environmental impact.

Trends in handled (used) quantities of chemicals subject to PRTR legislation(TACHI-S business locations in Japan)

※Due to the partial revision of the PRTR Law (April 1, 2023), the number of chemical substances contained in urethane raw materials has been increased.

Pollution Prevention

Efforts to Prevent Pollution

Due to the risk of chemicals polluting rivers, underground water, and soil, TACHI-S conducts tests and inspections to

prevent environmental pollution at individual locations, also performs emergency drills in a systematic manner.

Under the Water Pollution Prevention Act, we also regularly test wastewater discharged from individual locations into

public waters to confirm that we are satisfying environmental standards. TACHI-S has no facilities that lead to air

pollution and no incidences of soil pollution.

Environmental standards achievements for plant effluent(TACHI-S business locations in Japan※)

* The target business sites are the 3 sites that own septic tank sewage treatment facilities.

Preservation of Biodiversity

Basic Concept and Approach

Today, due mainly to the impact of human activity, species extinction on the Earth is occurring at a pace that is 100

to 1,000 times that of natural occurrence. Many living creatures are in danger of extinction and biodiversity is being

lost.

This is resulting in the degradation of biological services that support our abundant lifestyles and economic

activity, creating a demand for initiatives for the preservation of biodiversity on a worldwide scale.

Basic Policy on Biodiversity

Setting “kindness,” or consideration of nature, as the foundation of its manufacturing, TACHI-S will

strive to preserve biodiversity by reducing its impact on the global environment, with the aim of achieving a

sustainable society.

- We will identify the impacts of TACHI-S’s businesses on biodiversity.

- We will strive to reduce our impact on the global environment.

- We will pursue activities for the conservation of the natural environment.

- We will disclose information appropriately to Stakeholders.