By continuing “To live in harmony with individuals and society and to put smiles on people's faces by

continuously creating living spaces of comfort and enrichment” and convey trust and excitement to customers

around the world and contribute to the creation of a prosperous society.

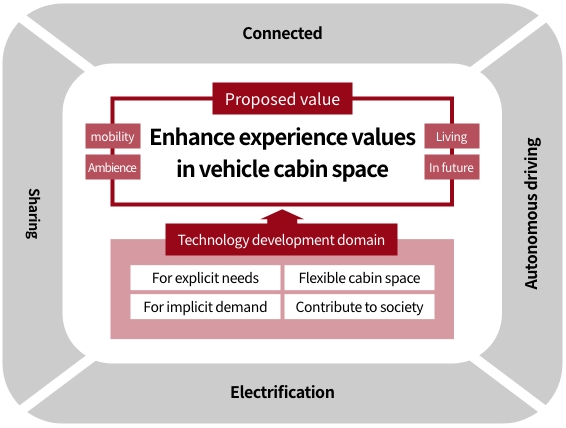

Toward Creating Social Value Through Our Products

The automobile industry in the midst major transformation is undergoing changes in various aspects such as the

environment, safety, and economy. In terms of ‟environment‟, technological development and material development are

progressing to reduce CO2 emissions, which is one of greenhouse gases, and efforts are being made to achieve the

SDGs. In terms of “safety,” safe driving support technology that prevents accidents by acquiring

information related to vehicle and road conditions with sensors has been evolving rapidly. In terms of

“economic ”, a business models that provide new value and services by collecting, accumulating, and

analyzing data acquired while moving via networks are being considered. In such a major transformation, it is

predicted that the way of spending time in the car cabin will change in the future. We believe that car

transportation will no longer be a mere means to travel, and the “offered value” and

“appeal” required of automobiles will change as well. We hope that we can meet the expectations of a

changing society by “enhancing experience values in vehicle cabin space” for various ways of time usage

and are strengthening technological development in the following areas

- “Pursuit of Seating”: For explicit needs and implicit demand, Body sensing, SW-less, anticipatory support

- “Supporting people”: For flexible cabin space, Easy space arrangement, privacy-friendly

- “Supporting the Earth”: To contribute to society, Environmental technologies and plant-derived materials

Examples of products that create social value

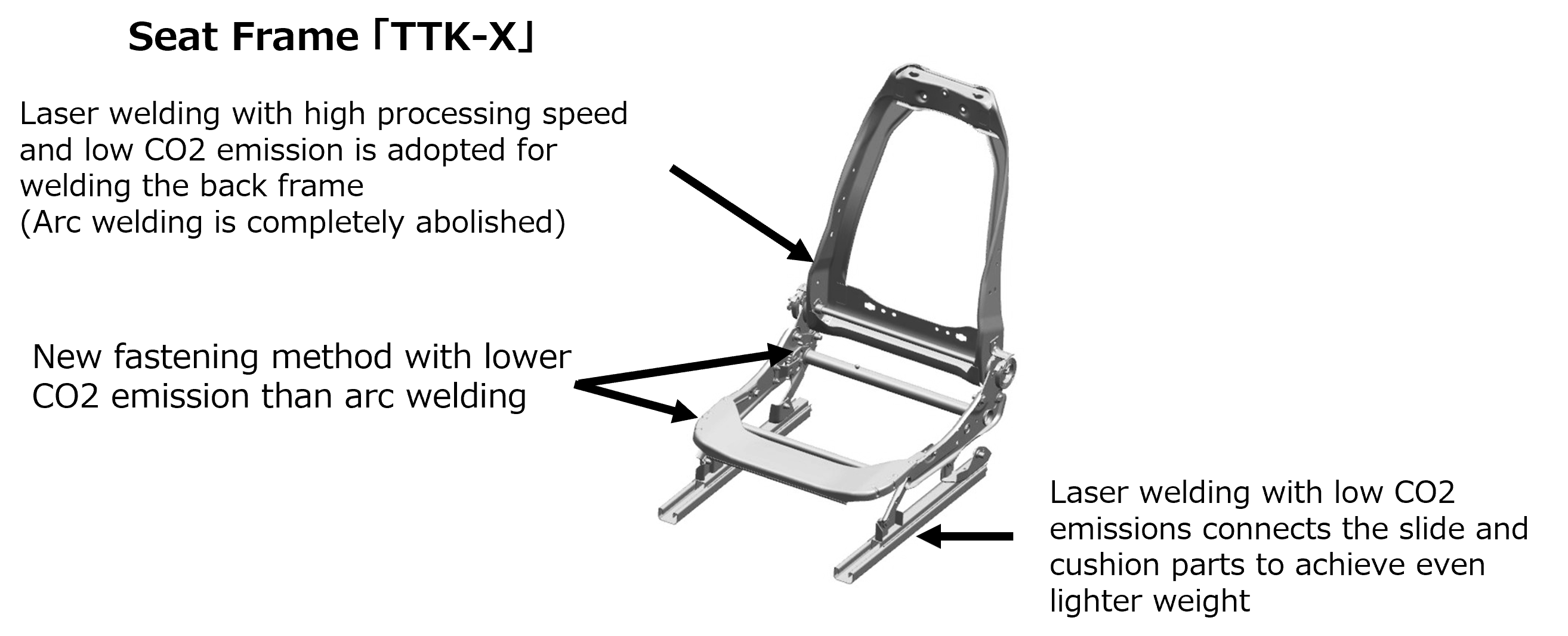

The “TTK Series” contributes to weight reduction

As part of our efforts to achieve carbon neutrality, we are working to reduce the weight of our sheets and adopt construction methods that emit less CO₂. The newly developed seat frame "TTK-X Frame" maintains and improves the safety and functionality of the product, while further expanding the application of laser welding and laminating pressed parts, achieving the lightest mass level in the industry, reducing the processing cost of the frame and reducing CO₂ emissions.

Developer’s voice

Takeshi Nishina , Product Design Department No.1, Product Design Section

“TTK 2.0 Kai” is a new Tachi-s proposed frame (TTK) using laser welding for the back frame and a

new fastening way for the cushion frame , to emits less CO2.

In the development phase, it was difficult to achieve compatibility in safety performance and marketability,

and to stabilize laser weld quality. Professionals from the development and production departments worked in

one-team to meet requirements different from before and cleared performance, commerciality, and productivity

targets. I think it is a frame that gathers everyone's strength. Even in an epidemic of COVID-19, the team

worked together positively and completed development.

This FRM is a new way of producing. Based on this, we will develop more advanced seats.

“Mobile My Room” concept for next generation vehicles

TACHI-S, as a space producer, is now trying to create values that focus on experience values though mobility and

seat -centered in-vehicle space. One of those studies is the “Mobile My Room” concept to address usage

for CASE. The single word for this concept is “1+α”. “1” expresses the current or

daily situation and is added with “+α”. Something will be “+α” dependent on

each life-style. In-vehicle space around seats, we think that this “+α” is offered to users, is

co-created with users.

- Mobile My Room for owners

- Space mainly for desk work

Such as work, study and sometimes take a break…

Place where you can concentrate on work.

- My Room +α

- Space for meeting with close friends / As a means of travel and also a room while traveling.

- Mobile living room for family

- Space to spend time with children without having worry about surroundings.

Place as second living room.

- Atelier for owner

- Personally specified room to immerse yourself in hobbies

(Secret base?)

Developer’s voice

Ukyo Miyazawa, Product Technology Development Department, Advanced Development Technology Section

In conjunction with reconsidering the whole concept of automobile seats, we had studied in-vehicle space to

meet various life-style in CASE era. By eliminating as much as possible elements which recall conventional

in-vehicle space, we believe that we could propose new value as you could feel having another room.

We will continue to study, propose and develop attractive in-vehicle space by being with users in the future.

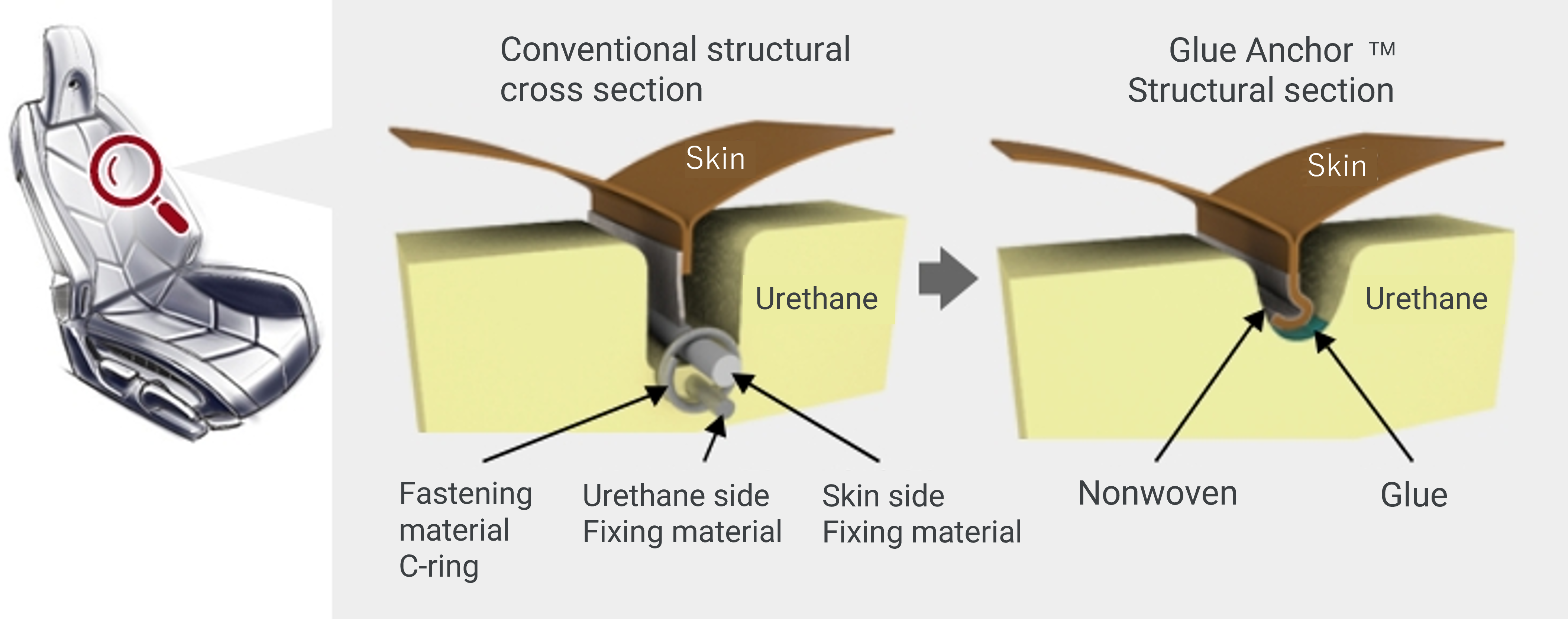

The "Glue Anchor®" that contributes to design freedom and the environment

We have succeeded in mass-producing the technology "Glue Anchor ®" that can contribute to the improvement of

design freedom and the global environment. This Glue Anchor® is a technology that glues the sewing line of the

trim cover directly to the urethane foam.

With conventional technology, it was not possible to express unevenness by joining complicated sewing lines to

urethane foam due to manufacturing restrictions, but this technology has made it possible. In addition, while the

conventional technique used point joining, this technology uses line joining. By joining with lines, it has become

possible to achieve stable and uniform unevenness up to the terminals where the sewing lines intersect.

In terms of the environment, reducing the weight of seats has become a major proposition in these days when CO2

emissions are required to be reduced. This technology can make urethane foam thinner than conventional technology

and contributes to weight reduction of seats. In addition, this technology is a resource-saving (lightening)

technology that can reduce the use of iron and resin compared to the conventional method.

Developer’s voice

Makoto Arai, Director, Foam & Plastic Parts Production Engineering Department

The "Glue Anchor®" is a joining technology of urethane foam and trim cover of TACHI-S Only One, which is

based on the existing technology and adds new elements to the essence. We firmly retained the idea that we

value in the know-how cultivated by the conventional construction method, and boldly innovated the part to be

changed to establish the technology. Although there were some difficulties in the development stage, we were

able to successfully complete the development and deliver it to our customers as the world's first technology.

The “Biomold Urethane Foam” A Sustainable Seat Material Solution

As part of our commitment to sustainability, we are developing a 'biomold urethane foam’ for automotive urethane pads that partially uses non-edible plant-based materials (castor oil).While aiming to reduce environmental impact, we strive to balance this with essential performance features such as comfort and durability, thereby contributing to the realization of a sustainable mobility society.

Developer’s voice

Takiwaki Kunikazu, Urethane Technology Expert

The development of Biomold Urethane Foam is an initiative aimed at creating environmentally friendly products by utilizing non-edible plant-based materials, specifically castor oil. In the development process, we are working to optimize foaming conditions and material formulations to ensure seating comfort and durability equivalent to conventional urethane. Currently, we are collaborating with internal and external members to solve numerous technical challenges toward mass production, and we remain committed to continuing this pursuit.

“Dialysis exercise therapy equipment” contributes to nursing care and welfare

TACHI-S H&P Co., Ltd., is our group company, is engaged in the nursing care and welfare products business. It

uses its knowledge as a seat manufacturer with the corporate objective of contributing to the improvement of welfare

in an aging society. One of the products TACHI-S H&P has developed is the “Dialysis exercise therapy

equipment.”Dialysis is standardized to be performed 4 hours/treatment, 3 times/week. Patients should avoid physical weakness

and muscle loss caused by prolonged hemodialysis treatment. The use of this product as an aid in dialysis exercise

therapy will improve the efficiency of dialysis and the quality of life of patients. This is the reason why we have

developed this product. This product is designed so that you can exercise in a limited space by attaching it to your

bed or table.

Developer’s voice

Takuro Yamamoto, Product Development Department, Product Development Section, TACHI-S H&P

The dialysis exercise therapy equipment is a product that is being developed based on the needs of

facilities. The need for exercise therapy is increasing due to the recent revision of reimbursement and the

increase in the average age of dialysis patients. We would like to promote the development of this product to

improve the efficiency of dialysis and life expectancy of patients. In the future, we aim to provide products

that satisfy both facilities and patients by verifying the effectiveness of our products and improving them

with the cooperation of facilities.